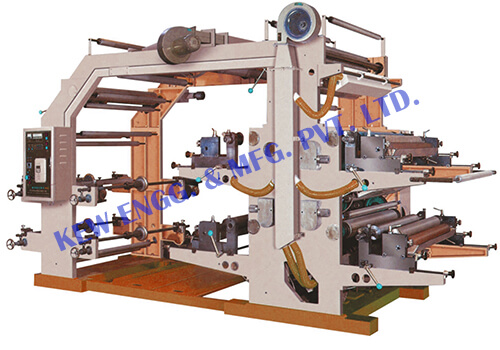

Flexo Printing Machine

- Standard Features

- Technical Specification

- Video

Standard Features

Flexo Printing Machine manufacturer, Our Flexo Printing Machine available in various sizes like: 18″, 20″, 22″, 24″, 26″, 28″, and 30″ in Four & Six Colors.

We have always readily available Printing Rollers with Gears for all sizes of Rubber Roll and doctor blade pneumatically or manually.

Tension controller Flexo Printing Machine designed with Motored registration control and many more features

Also, all type of high speed Rotogravure Printing Machine Manufacturer. We are winner of 3 times National Award and 2 times International Award for Quality manufacturing. For Flexo Printing Machine, we have processed all types of material like Paper, Non-Woven, HDPE, PP, Woven Sack, LD, BOPP, etc.

Technical Specification

Flexo Printing Machine

- High Printing speed to meet high – volume orders Precise Printing quality for superior reproductions Simultaneous two job Printing for more productivity, Energy saving for Lower operational costs Easy operational that saves labor.

- Registration Accuracy Strong and rebuts structure for Zero vibrations Quick Loading of Print Cylinders to minimize downtime Auto stop for Web Heater Thermostat for Power saving Helical Gears for Smoother movement Hard Chromed Anilox & Cylinder Rollers for Sharper Images Digital Counter Duplex System with to unwind and rewind stations to run two jobs at the same time Reveres printing – 1+5 or 2+4 or 3+3.

| Web Width Size | 20″ Web Width | 24″ Web Width | 30″ Web Width |

| Max Printing Width | 18″ |

22″ |

28″ |

| Print Repeat Min | 8″ | 8″ | 8″ |

| Print Length Max. | 36″ | 36″ | 36″ |

| Printing Speed | 0 – 60 Mts/Min. | 0 – 60 Mts/Min. | 0 – 60 Mts/Min. |

| Max. Parent Dia. | 30″ | 30″ | 30″ |

| Main Drive Motor | 3 HP D.C. | 3 HP D.C. | 3 HP D.C |

| A.C. Motor Blower | 3 HP D.C. | 3 HP D.C. | 3 HP D.C. |

| Heating Load | 13.5 kw | 13.5 kw | kw |

| Floor Space Required: | |||

| Length | 5.5 Mts | 5.5 Mts | 5.5 Mts |

| Width | 1.5 Mts | 1.5 Mts | 1.5 Mts |

| Height | Mts | 3 Mts | 3 Mts |

| Weight (Approx.) | 3200 Kgs | 3200 Kgs | 3200 Kgs |

Video

Products

- 39Tyre Cord and Technical Textiles Machinery

-

- Liner Rewinder Machine

- Fabric Re Rolling Machine

- High Efficiency Inspection Machine Batching Machine

- Let Off Stand

- 18Equipments Tyre Cord Dipping Plant

-

- Two Stage Let Off Station

- Automatic Web Tension Control System

- Curved Bar Expander

- Feed Roll System

- Let Off Accumulator

- Center Guiding System

- Fabric Dipping Tank

- Stretch Heat Zone

- Web Master Centering Device

- Hot Stretch

- Intermediate Guiding

- Cooling Roll System

- Automatic Centering System

- Wind Up Accumulator

- Pull Roll

- Automatic Web Guiding Systems

- Trio Canter

- Two Stage Winder

- 10Equipments Calendering Plant

- Liner Drying Machine

- Automatic Festoon Accumulator

- Material Handling System

- Automatic Guiding System

- Cooling Heating Drums

- Core Cutting Machine

- Hydro Pneumo Web Aligner

- 18Equipments

- 17Textile Processing Machinery

-

- Stenter Machine

- Jigger Machine

- Bowl Mangle Drying Range

- Float Dryer

- Relax Dryer

- Feeder Machine Fabric Infeed Device

- Cloth Guider

- Folding Machine

- Cloth Inspection Machine

- Spares Textile Processing Machinery

- Trolly Material Handling System

- Hot Air Stenter Machine

- Open Batching Stenter Machine

- Super Jumbo Jigger

- Semi Automatic Maxi Close Type Jumbo Jigger Machine

- Semi Jigger

- Spares Stenter

- 19Flexible Packaging and Converting Machinery

-

- Rotogravure Printing Machine

- Flexo Printing Machine

- Lamination Machine

- Coating Machine

- Slitter Rewinder Machine

- Inspection Rewinding Machine

- Doctoring Rewinding Machine

- BOPP Slitter Rewinder

- Rotogravure Online Lamination

- Rotogravure Flexo on Extruder

- Core Cutter Machine

- BOPP Slicer Machine

- BOPP Cutting Machine

- Rewinder Unwinder

- Roll Wrapping Machine

- Winding Rewinding Machine

- Web Guiding System

- Trim Rewinder

- Folding Open Machine

- 3Paper Industries Machinery

- 3Repairing and Servicing